Automotive electronics are the combination of electronic information technology and traditional vehicle technology, and are the general name of vehicle body electronic control and vehicle electronic control.

The degree of automobile electronics is considered as an important symbol to measure the level of modern automobiles. It is an essential technical measure to develop new models and improve the performance of automobiles. Under the impetus of Tesla, the industry is located in the process of rapid rise. PCB is commonly used in automotive electronics, which are involved in the four systems, such as power control system, safety control system, body electronic system and entertainment communication. Therefore, the requirements for PCB are diversified, and the low price products coexist with high reliability requirements: single and double board, 4 laminate, 6 laminate, 8- in vehicle PCB The proportion of 16 laminate is 26.93%, 25.70%, 17.37% and 3.49%, and the total ratio is about 73%. The proportion of HDI, FPC and IC board is 9.56%, 14.57%, 2.38%, and the total ratio is about 27%.

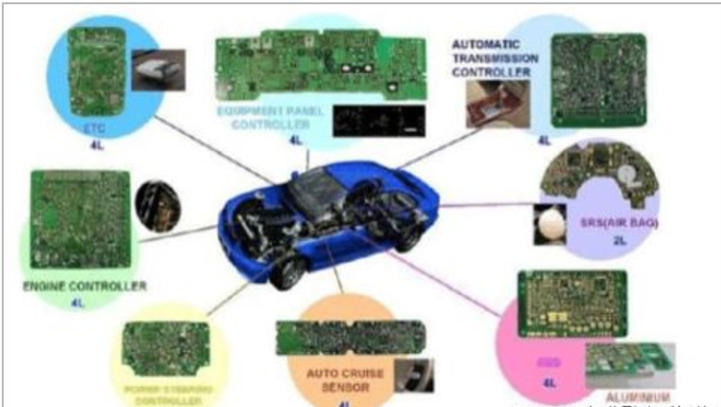

Application of PCB in automobile

The average PCB consumption of a single car is 55 dollars in 2016, and the average PCB consumption of a lone car will reach 65 dollars by 2020. The PCB of the compact car is 18-30 yuan. The middle class vehicle consumption is 40-60 yuan, and the luxury vehicle PCB consumption is 120-150 dollars. In 2016, the global vehicle output reached 94 million 976 thousand and 600 vehicles, an increase of 4.5% over the same period, of which 28 million 118 thousand and 800 of the total vehicle output in the Chinese market increased by 14.5% compared to the same period last year. If considering the current stock market, the average PCB value of the single car was raised from $55 in 2016 to $65 in 2020, then the global car demand for PCB was about $950 million, equivalent to 19.2% of the 2016 car PCB market and 4.51% in the 2016-2020 year industry. The new energy vehicle's vehicle controller (VCU), the motor controller (MCU) and the battery management system (BMS) have increased the value of the single vehicle PCB by more than 2000 yuan, which is much more than the increase of intelligence and light weight. Therefore, in addition to automotive electronic upgrading, the rapid penetration of new energy vehicles in the support of national policies will be the main growth point of vehicle PCB.